-

Multifunctional Handheld Infrared Night Vision

-

Explosive Ordnance Disposal Robot

-

Miniature Reconnaissance Robot

-

Monocular Digital Night Vision

-

Digital Night Vision Device

-

Anti Sniper

-

Portable Radar

-

Patrol Recording Flashlight

-

Tactical Special Operations Equipment

-

Rifle Scope

-

Laser Rangefinder

-

Military Model

-

Tactical Gear

-

Inflatable Decoys

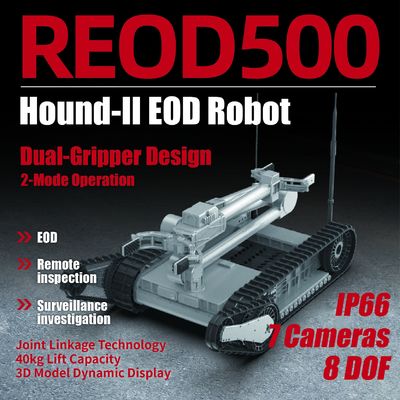

X-Y-Z Coordinate Robotic Arm Medium Sized EOD Robot

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Features | 1. High-strength Mechanical Arm Design, Endows Powerful Snatch Performance;2."Christie" Suspension Track System, Complex Terrain Like Walking On Flat Ground;3.Graphically Dual-mode Operation, Convenient And Reliable Operation Experience;4.Remote 3D Real-ti | Maximum Speed | ≥2m/s(5 Gears, Continuously Variable) |

|---|---|---|---|

| Special Features | Explosion-proof, Waterproof, Remote Disarming Capability | Product Name | Mission Objectives Hound-III EOD Robot For Disposal Measures And Hazard Transfer |

| Robot Platform Weight | ≤350kg(Contain Batteries); | Robot Platform Wading Depth | ≥500mm; |

| Applications | Responding To Improvised Explosive Devices | Robot Platform Size | 1600×850×1300 Mm(Fully Stowed); |

| Robot Size | ≤950×650×650mm(Fully Stowed) | Robot Weight | ≤50kg(Contains Two Sets Of Batteries) |

| Over Obstacle Ability | ≥400mm | Across Groove Width | ≥400mm |

| Gradeability | ≥45° | Climb Stairs | ≥45° |

| Wading Depth | ≥200mm | Battery Life(Normal Temperature) | ≥3h |

| Arm Length | 2000mm | Maximum Snatch Weight | ≥40kg |

| Claws | 2 | Movable Joints | 8 |

| Controller Size | ≤270mm×170mm×100mm | Controller Weight | ≤1.2kg(Without Backpack) |

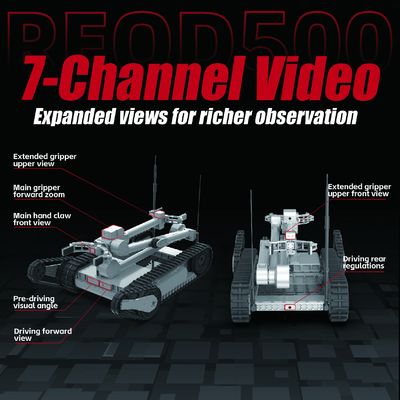

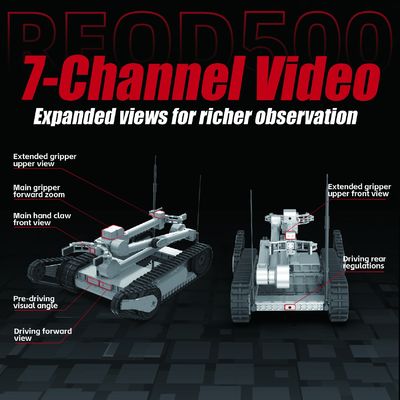

| Controller Display Screen | 7'' LCD | Video Display | 7-channel,one Of Which Has Auto Focus Zoom Function |

| Operation Method | Dual-mode Operation Of Button Rocker And Touch Screen | Control Method | Cable Control≥100m(Standard Cable),Wireless Control≥1000m(Outdoor) |

| Robot Platform IP Grade | IP66 | Arm IP Grade | IP66 |

| Operating Temperature | -40℃~+50℃ | Storage Temperature | -45℃~+60℃ |

| Highlight | Coordinate Robotic Arm Explosive Ordnance Disposal Robot,Medium Explosive Ordnance Disposal Robot,IP66 robots eod |

||

Advanced X-Y-Z Coordinate Robotic Arm Medium-Sized EOD Robot Manufacturers

Description And Features

The JP REOD500 EOD Robot is an advanced solution for explosive ordnance disposal (EOD) in high-risk environments. Featuring a swing-arm crawler system that combines the main crawler with a swing-arm obstacle mechanism, this design significantly improves the robot's obstacle-navigation capabilities, ensuring robust and reliable performance in EOD operations. The robot is equipped with a multi-degree-of-freedom robotic arm that provides powerful grasping and handling capabilities. The JP REOD500 has dimensions of ≤900mm × 650mm × 500mm (fully stowed) and a weight of ≤42kg. It has a maximum speed of ≥2.0m/s, an obstacle clearance of ≥320mm, and a gradeability and stair climbing ability of up to 45°, ensuring superior maneuverability in various terrains.

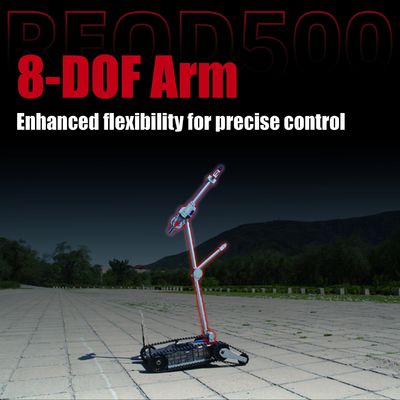

Equipped with an 8-degree-of-freedom Manipulator, the JP REOD500 offers precise control with a maximum gripping height of ≥1800mm (main claw) and a farthest grabbing distance of ≥1400mm (main claw). The robot supports a 7-channel video display, enabling richer observation perspectives, and features remote 3D posture real-time display capabilities. With a battery life of ≥3 hours at normal temperature, an IP67 rating for dust and water resistance, and control methods that include cable control up to 120m and wireless control up to 1200m, the JP REOD500 is built for reliability and versatility in challenging conditions. Additionally, it offers OEM and ODM customization options to meet specific operational needs.

Enhanced Mechanical Arm Design — Greatly Improved Gripping Performance

The JP REOD500 features an enhanced mechanical arm design that significantly improves its gripping capabilities. This advanced design enables the robot to handle a variety of hazardous objects with greater precision and strength, enhancing the overall efficiency of EOD operations.

Innovative "2-Claws" Patent Design — Multi-Task Capabilities

The patented "2-claws" design allows the JP REOD500 to solve multiple tasks simultaneously. With both a primary claw and an auxiliary claw, the robot can perform complex operations, such as gripping objects while opening doors or performing other auxiliary tasks, making it highly effective for EOD missions.

Graphically Dual-Mode Operation — Convenient and Reliable Operation Experience

The graphical dual-mode operation provides users with an intuitive interface for controlling the robot. Both touchscreen and joystick controls are supported, ensuring ease of use and reliability in high-stress environments. This design eliminates the need for users to memorize complex button functions, reducing training time and improving operational efficiency.

Remote 3D Real-Time Display — Fine Operation in Front of Your Eyes

The JP REOD500 utilizes advanced 3D virtual display technology for real-time feedback of the robot's status. This feature enables operators to view the robot's 3D status from various angles, providing an intuitive and detailed understanding of the robot's positioning and environment, even when it is operating beyond the line of sight.

Intelligent Preset Control Design — Personalized Setting of Working Posture

The intelligent "preset" control design allows the JP REOD500 to automatically reach preset positions with one click, based on the user's needs. This feature simplifies the operation process, reducing the amount of manual intervention required and ensuring quick and reliable task execution.

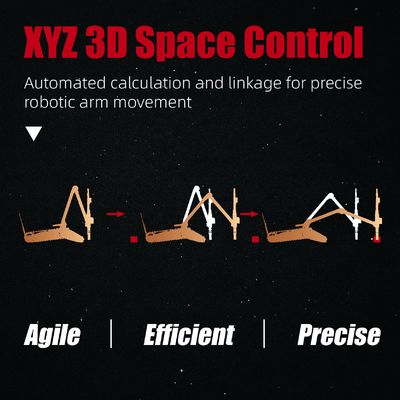

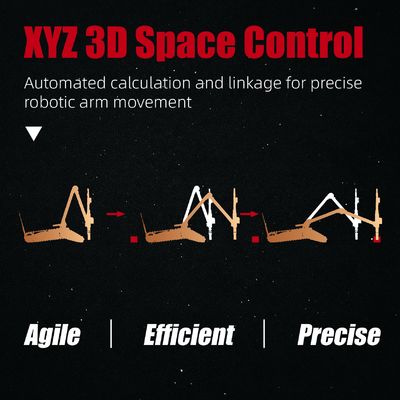

"X-Y-Z" Three-Dimensional Space Robotic Arm Linkage Design — Precise Control

The JP REOD500 employs an "X-Y-Z" three-dimensional robotic arm linkage design based on automatic calculation, providing precise control over the robot's movements. This design enhances the efficiency and accuracy of bomb disposal tasks, reducing the average operation time by up to 80% compared to traditional single-joint control.

7-Channel Video System — Richer Observation Perspectives

Equipped with a 7-channel video system, the JP REOD500 provides multiple observation angles to enhance situational awareness. The imaging system automatically switches between driving mode, primary gripper mode, and auxiliary gripper mode, adapting to the operational context for optimal viewing.

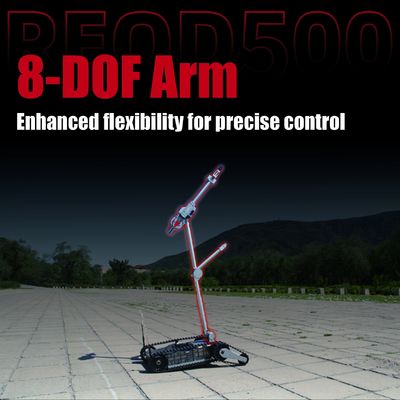

8-Degree-of-Freedom Robotic Arm Design — More Flexible Control

The 8-degree-of-freedom robotic arm design gives the JP REOD500 strong spatial reach capabilities, allowing it to perform tasks in high, low, deep pit, or tabletop environments. This flexibility makes it suitable for a wide range of EOD operations that require precision and adaptability.

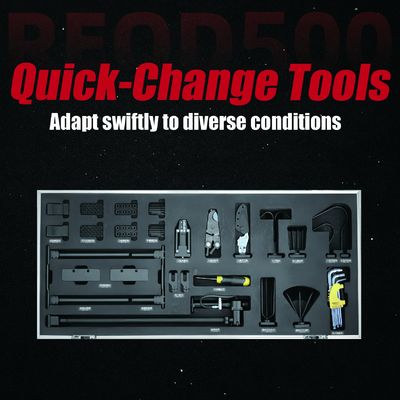

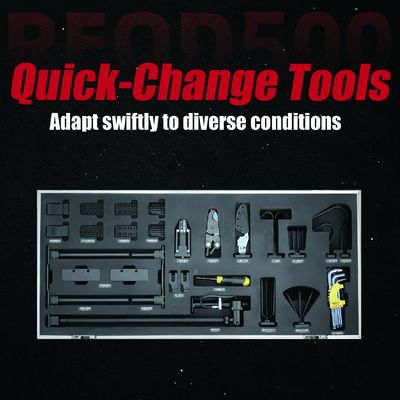

Versatile Quick-Change Tool System — Adaptable to Various Working Conditions

The JP REOD500 is equipped with a versatile quick-change tool system, including multiple gripping tool sets, basic tool sets, and extended tool sets. These tools can be quickly swapped out based on the specific operational requirements, enabling the robot to adapt seamlessly to various working conditions and effectively tackle different types of hazards.

Applications

Image Gallery

Technical Parameters

| Robot Platform | |

|

Size |

≤950×650×650mm(Fully Stowed) |

|

Weight |

≤50kg(Contains two sets of batteries) |

|

Maximum Speed |

≥2m/s(5 gears, continuously variable) |

|

Over Obstacle Ability |

≥400mm |

|

Across Groove Width |

≥400mm |

|

Gradeability |

≥45° |

|

Climb Stairs |

≥45° |

|

Wading Depth |

≥200mm |

|

Battery Life(Normal temperature) |

≥3h |

|

Robotic Arm Grabbing Performance |

|

|

Arm Length |

2000mm |

|

Maximum Snatch Weight |

≥40kg |

|

Claws |

2 |

|

Movable Joints |

8 |

|

Portable Controller |

|

|

Size |

≤270mm×170mm×100mm |

|

Weight |

≤1.2kg(Without backpack) |

|

Display Screen |

7'' LCD |

|

Video Display |

7-channel,one of which has auto focus zoom function |

|

Operation Method |

Dual-mode operation of button rocker and touch screen |

|

Control Method |

Cable control≥100m(Standard cable),Wireless control≥1000m(Outdoor) |

|

Protection level and environmental adaptability |

|

|

Robot Platform |

IP66 |

|

Arm |

IP66 |

|

Operating Temperature |

-40℃~+50℃ |

|

Storage Temperature |

-45℃~+60℃ |

Contact Us

Ms. Amy

Email : amy-huang@mysmech.com